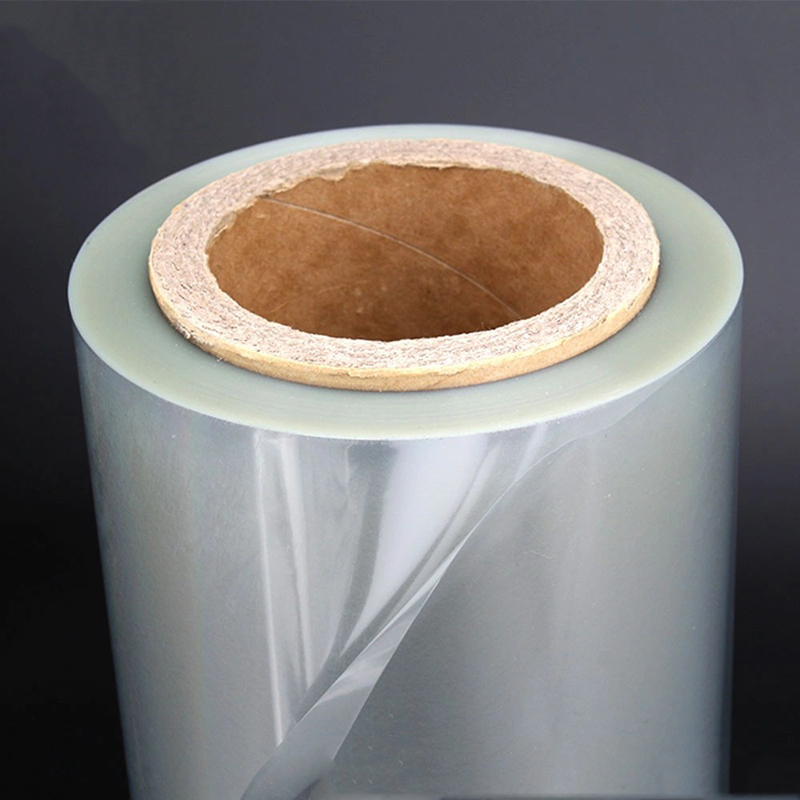

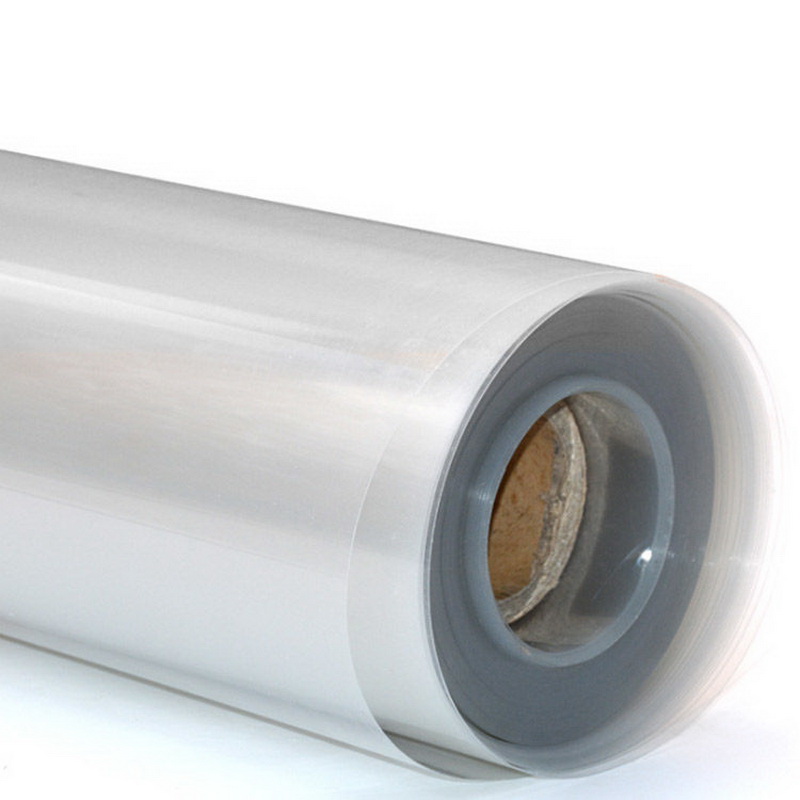

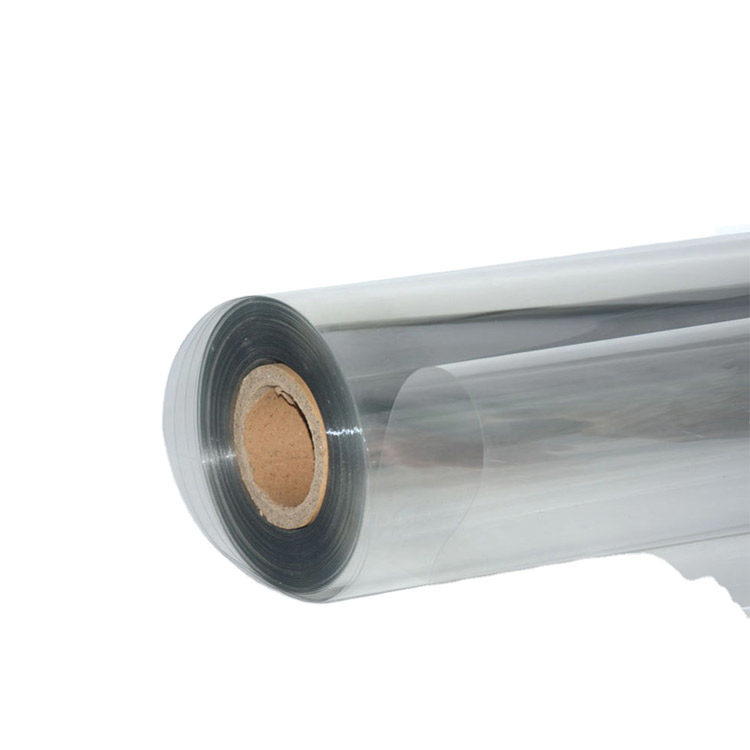

0.4mm PET plastic sheet rolls

PET-SHEET.COM

PET-SHEET.COM

- Límites de producción:

- Gama de espesores: 0.18mm-1.8mm

- Gama de anchos: 350mm-1300mm

- Gama de colores: Transparente/Transparente/Negro/Blanco/Color personalizado

- MOQ: 5 toneladas (se aceptan muestras gratis)

- Aplicaciones: Bandeja termoformada / Bandeja electrónica / Bandeja para alimentos frescos / Envasado blíster

¿Está buscando esto? Thermoforming PET Sheet Roll. pet-sheet.com is Una fábrica enfocada en la fabricación y exportación de rígido Thermoforming PET Sheet Roll para termoformado o envasado en blíster. en cuanto a "0.4mm PET plastic sheet rolls", Si nos deja sus requisitos como el grosor, ancho y aplicación del plástico PET, nuestro equipo de ventas profesional le cotizará el mejor precio competitivo.

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

Introduction of 0.4mm PET plastic sheet rolls

0.4mm PET plastic sheet rolls are versatile materials commonly used in various applications, including packaging, printing, and construction. These rolls offer excellent clarity, chemical resistance, and durability.

Key Features

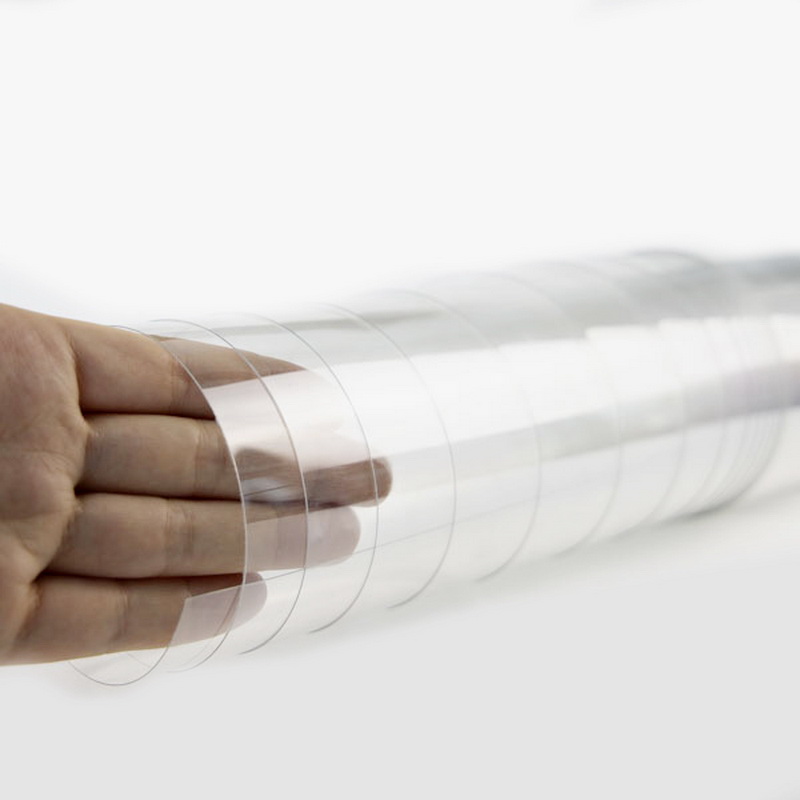

Thickness: 0.4mm provides a balance between flexibility and rigidity.

Transparency: High clarity for aesthetic appeal in packaging.

Lightweight: Easy to handle and transport.

Recyclability: PET plastic sheet roll is a recyclable material, making it an eco-friendly option.

Applications: Suitable for packaging of various products

Advantages of 0.4mm PET plastic sheet rolls

The characteristics of 0.4mm PET plastic sheet rolls include: excellent transparency, weather resistance and chemical resistance, light weight and easy processing, good impact resistance and dimensional stability. In addition, it also has high heat resistance and UV resistance, suitable for various packaging.

1. Excellent transparency: Provides high light transmittance, making product display clearer and attracting customers’ attention.

2. Weather resistance: 0.4mm PET plastic sheet rolls can resist the influence of environmental factors such as sunlight and rain, suitable for outdoor use, and reduce maintenance costs.

3. Chemical resistance: 0.4mm PET plastic sheet rolls strong resistance to oil, solvents and other chemicals, protecting internal items from corrosion.

4. Lightweight: Compared with traditional materials, it reduces transportation costs and the burden of manual handling, which is convenient and efficient.

5. Good impact resistance: 0.4mm PET plastic sheet rolls can effectively absorb external impact force, ensure the safety of internal items, and reduce the risk of breakage.

Dimensional stability: Maintains shape and size stability under changes in temperature and humidity, suitable for long-term storage.

6. Heat resistance: 0.4mm PET plastic sheet rolls can maintain physical properties at higher temperatures, suitable for thermal processing and food packaging.

7. Anti-ultraviolet ability: 0.4mm PET plastic sheet rolls can reduces damage to materials caused by ultraviolet rays, prolongs service life, and is suitable for applications exposed to sunlight for a long time.

Application of 0.4mm PET plastic sheet rolls

0.4mm PET plastic sheet rolls have a variety of uses, including:

1. Packaging: 0.4mm PET plastic rolls widely used in food packaging, cosmetic containers, and retail products due to its clarity and durability.

2. Protective Covers: Used for electronics and fragile items to protect against dust, moisture, and impact.

3. Medical Applications: Used for packaging of medical devices and products to ensure hygiene and safety.

4. Crafts: Popular in creative projects for scrapbooking, crafting, and DIY applications.

5. Industrial Uses: Used for packaging of equipment for a variety of industrial applications.

Parameter of 0.4mm PET plastic sheet rolls

| Product name | 0.4mm PET Plastic Sheet Rolls, Polyethylene Terephthalate Sheet, PET Plastic Roll, Polyester Sheet, Rigid PET Film. |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

| Shape | Roll/Sheet |

| Thickness | 0.18~2.0mm |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

| PET Roll Diameter | ≤38 inch |

| Die Cutting Size | A2, A3, A4 or customized according to requirements. |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting. |

| Hardness | Rigid/Semi-rigid |

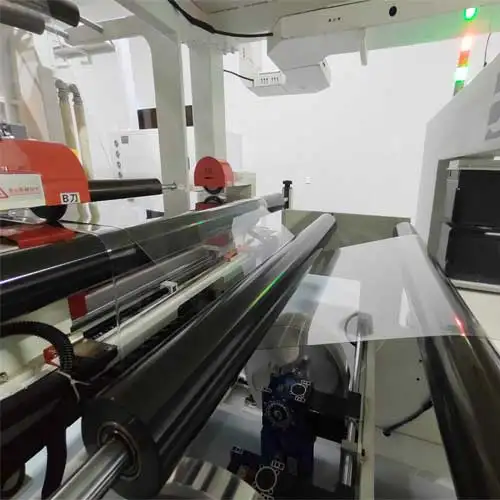

Production of 0.4mm PET Plastic sheet rolls

The production of 0.4mm PET plastic sheet rolls typically involves the following steps:

1. Material Preparation: High-quality PET resin pellets are dried to remove moisture, ensuring optimal processing.

2. Extrusion: The dried PET resin is fed into an extruder, where it is melted and formed into a continuous sheet. The extrusion process involves heating the resin to a temperature that allows it to flow and be shaped.

3. Calendering: The extruded PET plastic sheet rolls is passed through a series of rollers (calendering) to achieve the desired thickness of 0.4mm. The calendering process also helps to improve the sheet’s surface finish.

4. Cooling: The PET plastic sheet rolls is then cooled to solidify its shape. This can be done using a cooling roller or air cooling methods.

5. Trimming and Slitting: Once cooled, the edges of the sheet are trimmed, and the sheet is cut into rolls of the desired width.

6. Quality Control: Throughout the process, quality checks are performed to ensure the thickness, clarity, and surface finish meet specifications.

7. Packaging: The finished rolls are packaged for shipment, ensuring they are protected from damage during transport.

Storage of 0.4mm PET Plastic sheet rolls

To store 0.4mm PET plastic sheet rolls, keep them in a cool, dry environment away from direct sunlight. Stack rolls vertically to avoid deformation, ensuring they are on a flat surface. Maintain a consistent temperature and humidity level to prevent warping or damage. Regularly inspect for any signs of wear or moisture buildup.

To store 0.4mm PET plastic sheet rolls effectively, consider the following guidelines:

1. Temperature and Humidity: Keep the storage area cool and dry. Ideal temperatures are between 15-25°C (59-77°F), with low humidity levels to prevent condensation.

2. Positioning: Store rolls vertically to avoid deformation. If stacked, ensure they are on a flat surface and not overloaded to prevent crushing.

3. Protection from Light: Keep the rolls away from direct sunlight or harsh artificial light to prevent degradation of the material.

4. Ventilation: Ensure good air circulation in the storage area to minimize moisture buildup.

5. Dust and Contaminants: Cover the rolls with a breathable material to protect against dust and contaminants while allowing air circulation.

6. Handling: Use proper lifting techniques to avoid damaging the rolls during movement.

Following these practices will help maintain the quality of the 0.4mm PET plastic sheet rolls for longer periods.

¿Por qué elegir pet-sheet.com?

Producción de coextrusión

Producción de coextrusión

Inspeccion de calidad

Inspeccion de calidad

Embalaje seguro

Embalaje seguro

El tiempo de entrega

El tiempo de entrega

CONTACTO PET-SHEET.COM

Nuestro equipo de ventas profesionales y técnicos determinarán las características finales del producto y la solución material para la aplicación específica del cliente y proporcionarán al cliente una cotización y un cronograma detallado. Por favor, complete el formulario para contactar a nuestro equipo de ventas profesional.- Categoría

- Rollo de lámina de plástico APET

- Rollo de lámina de plástico GAG

- Rollo de lámina de plástico PETG

- Rollo de lámina de plástico RPET

- Rollo de lámina PET antiestática ESD

- Termoformado de PET en rollo

- Similar Products No related posts found.

PET-SHEET.COM

PET-SHEET.COM