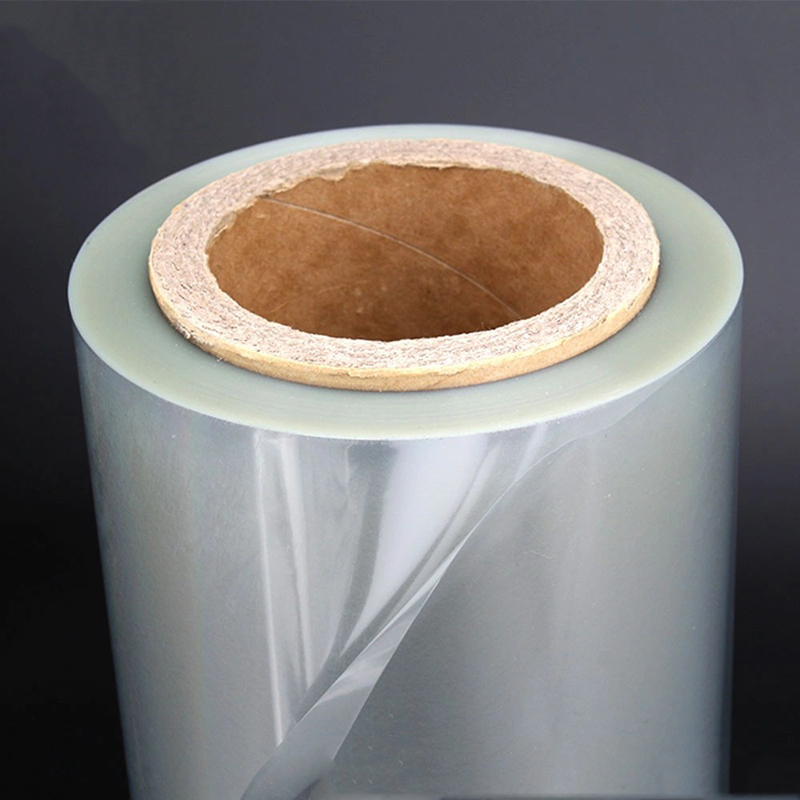

1.5 mm Pet plastic sheet roll

PET-SHEET.COM

PET-SHEET.COM

- Límites de producción:

- Gama de espesores: 0.18mm-1.8mm

- Gama de anchos: 350mm-1300mm

- Gama de colores: Transparente/Transparente/Negro/Blanco/Color personalizado

- MOQ: 5 toneladas (se aceptan muestras gratis)

- Aplicaciones: Bandeja termoformada / Bandeja electrónica / Bandeja para alimentos frescos / Envasado blíster

¿Está buscando esto? Thermoforming PET Sheet Roll. pet-sheet.com is Una fábrica enfocada en la fabricación y exportación de rígido Thermoforming PET Sheet Roll para termoformado o envasado en blíster. en cuanto a "1.5 mm Pet plastic sheet roll", Si nos deja sus requisitos como el grosor, ancho y aplicación del plástico PET, nuestro equipo de ventas profesional le cotizará el mejor precio competitivo.

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

Product introduction of 1.5 mm Pet plastic sheet roll

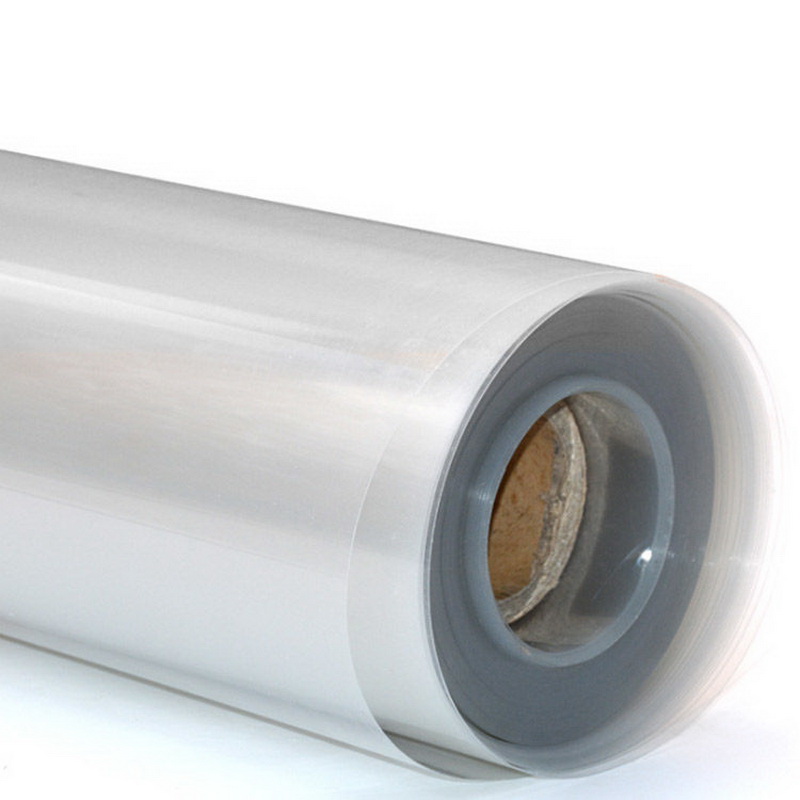

1.5 mm PET plastic sheet roll refers to a roll of plastic sheets made from polyethylene terephthalate (PET) material, and the thickness of each sheet is 1.5 millimeters. PET is a commonly used thermoplastic polymer in the production of various plastic products. It is known for its transparency, lightweight nature, and recyclability.

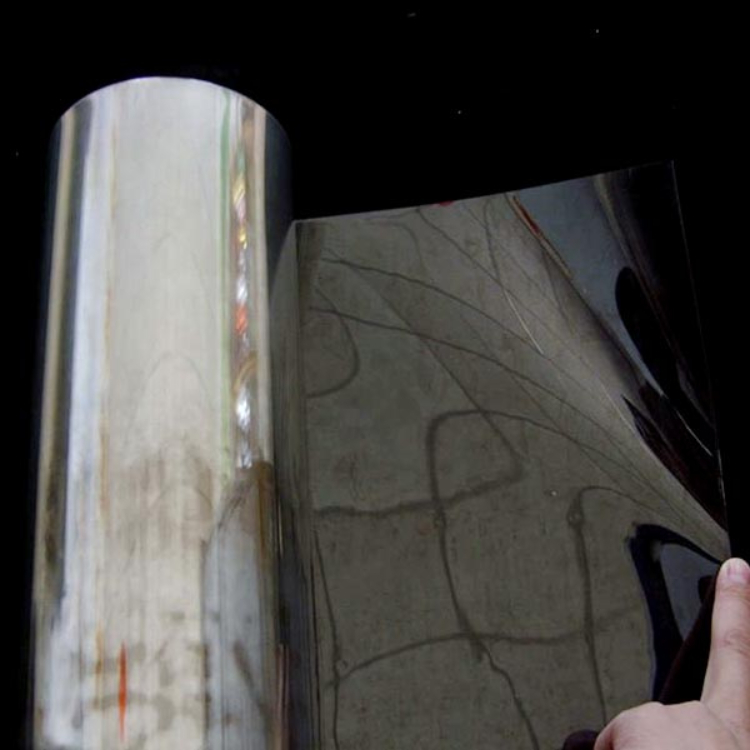

The use of 1.5 mm PET plastic sheet rolls can vary depending on specific needs and applications. PET plastic sheets are often used in packaging and other industries where a durable, transparent, and flexible material is required. The sheets can be cut to size and shaped as needed for different purposes.

Product parameter of 1.5 mm PET plastic sheet roll

| Product name | 1.5 mm PET Plastic Sheet Roll, PET Plastic Sheet, Polyethylene Terephthalate Sheet, PET Plastic Roll, Polyester Sheet, Rigid PET Film. |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

| Shape | Roll/Sheet |

| Thickness | 1.5 mm |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

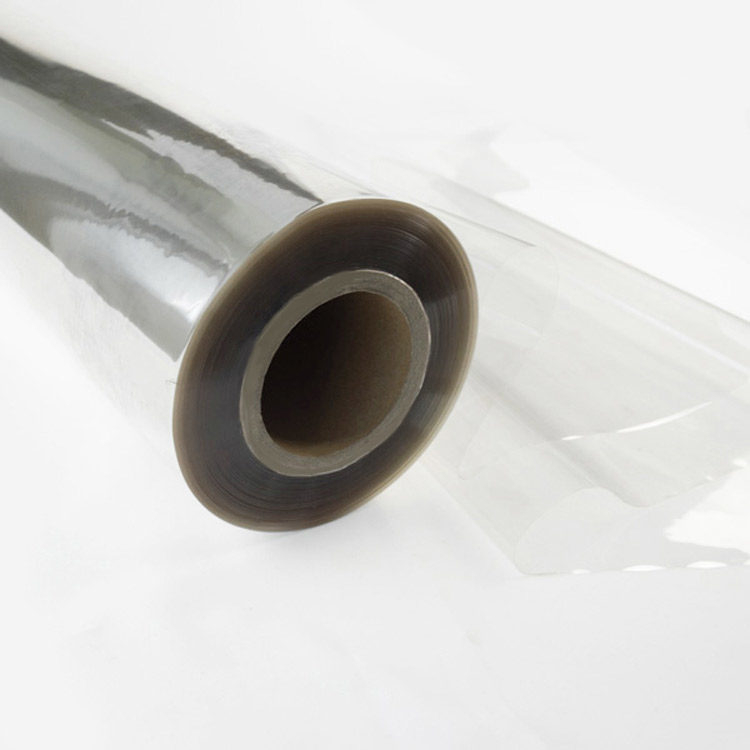

| PET Roll Diameter | ≤38 inch |

| Die Cutting Size | A2, A3, A4 or customized according to requirements. |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting. |

| Hardness | Rigid/Semi-rigid |

Product advantage of 1.5 mm PET plastic sheet roll

1. Good rigidity: The thickness of the PET roll is a key factor affecting the strength and rigidity of the roll. Therefore 1.5mm PET plastic sheet rolls have good rigidity.

2. High strength: PET has relatively high strength, which allows the 1.5 mm PET sheet roll to maintain stability when subjected to stresses such as tension and bending.

3. Moderate hardness: The hardness of 1.5mm PET plastic sheet rolls is moderate and has a certain degree of rigidity without being too brittle and hard.

4. Transparency: 1.5mmPET plastic sheet rolls generally have good transparency, which makes them excellent in applications that require transparent or translucent properties.

5. Electrical insulation: 1.5mm PET plastic sheet rolls are electrical insulation materials, suitable for electronic and electrical fields, and can be used to make cable insulation materials.

6. Chemical stability: 1.5mm PET plastic sheet rolls have good stability to some common chemicals, but use in special chemical environments still needs to be considered.

7. Wear Resistance: 1.5mm PET plastic sheet rolls generally have good wear resistance, making them excellent in applications that require frequent handling or friction.

8. Recyclability: 1.5mm PET plastic sheet rolls are recyclable plastic, which helps reduce the need for new raw materials and is in line with the concept of sustainable development.

9. Temperature stability: 1.5mm PET plastic sheet rolls are stable within a certain temperature range, but may soften at high temperatures, so temperature requirements need to be considered based on specific applications.

10. Formability: 1.5mm PET plastic sheet rolls are easy to process and form, and are suitable for various production processes, such as extrusion, injection molding, etc.

11. Barrier properties: 1.5mm PET plastic sheet rolls usually have good gas and moisture barrier properties and are suitable for the manufacture of some packaging materials.

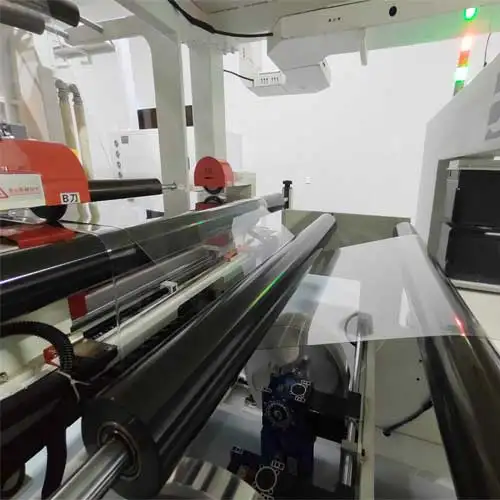

Production process of 1.5mm PET plastic sheet roll

1. Raw Material Preparation

(1) Polyethylene Terephthalate (PET) Resin: Select high-quality PET resin, often in pellet form.

(2) Additives: Include stabilizers, colorants, and other modifiers as needed for specific properties.

2. Drying

Dehumidifying Dryers: Dry the PET pellets to remove moisture content (typically below 0.1%) to prevent hydrolysis during processing.

3. Extrusion

(1) Extruder Feeding: Feed the dried PET pellets into the extruder.

(2) Melting: Heat the pellets in the extruder to melt them, usually at temperatures around 250-280°C (482-536°F).

(3) Mixing: Ensure uniform mixing of any added additives.

4. Sheet Formation

(1) Die Extrusion: Melted PET is forced through a flat die to form a continuous sheet.

(2) Cooling: The extruded sheet is rapidly cooled using chill rolls or air to maintain thickness and prevent warping.

5. Calendering (if applicable)

(1) Thickness Adjustment: The sheet may be passed through calender rolls to achieve the desired thickness (1.5 mm).

(2) Surface Finishing: Calendering can also improve surface smoothness and gloss.

6. Cutting

Sheet Cutting: Once cooled, the sheet is cut into the desired width and length for rolls.

7. Winding

Roll Formation: The sheets are wound onto cores to form rolls, ensuring uniform tension to avoid wrinkles.

8. Quality Control

(1) Inspection: Conduct tests for thickness, clarity, and surface defects. Ensure compliance with specifications.

(2) Physical Properties Testing: Evaluate mechanical properties such as tensile strength and flexibility.

9. Packaging

(1) Protective Packaging: Wrap the rolls in protective film and label them for storage and shipment.

Storage:

(2) Conditioning: Store the finished rolls under appropriate conditions to maintain quality until delivery.

Product application of 1.5 mm PET plastic sheet roll

The 1.5 mm PET plastic sheet roll is widely used in the packaging field, and the following are some of our regular applications in the packaging field.

1. Food packaging: 1.5mm PET plastic sheet rolls are often used in food packaging. For example, transparent films can be used to package candy, chocolate, pastries and other food products. PET’s transparency helps reveal the product inside the package.

2. Pharmaceutical packaging: 1.5 mm PET sheet rolls can be used to make pharmaceutical packaging materials, such as pharmaceutical blisters, pharmaceutical bags, etc. PET’s stability to chemicals also makes it a suitable choice for pharmaceutical packaging.

3. Electronic product packaging: Due to the electrical insulation of PET, 1.5mm PET sheet rolls can be used for packaging of electronic products to protect products from static electricity or other electrical interference.

4. Daily necessities packaging: Suitable for packaging various daily necessities, such as toiletries, cleaning supplies, etc. PET’s abrasion resistance and strength enable it to protect the products within the packaging.

5. Toy packaging: 1.5mm PET sheet rolls can be used for toy packaging to protect the toys and display their appearance.

6. Cosmetic packaging: PET’s transparency and formability make it an option for cosmetic packaging that can showcase the color and appearance of cosmetics.

Storage Notes of 1.5 mm PET Plastic Sheet Roll

1. Temperature Control: Store in a cool, dry place. Ideal temperature range is between 15°C and 25°C (59°F – 77°F).

2. Humidity: Maintain low humidity levels to prevent warping or deformation. Aim for 40-60% relative humidity.

3. Avoid Direct Sunlight: Keep rolls away from direct sunlight to prevent discoloration and degradation of material.

4. Flat Storage: Store rolls horizontally on a flat surface to avoid pressure points and maintain shape.

5. Handling: Use proper lifting techniques to avoid bending or damaging the sheets during movement.

6. Packaging: Keep rolls in original packaging until ready for use to protect from dust and contaminants.

7. Inspection: Regularly inspect stored rolls for any signs of damage or degradation.

Following these guidelines will help maintain the quality and integrity of the 1.5 mm PET plastic sheet rolls.

¿Por qué elegir pet-sheet.com?

Producción de coextrusión

Producción de coextrusión

Inspeccion de calidad

Inspeccion de calidad

Embalaje seguro

Embalaje seguro

El tiempo de entrega

El tiempo de entrega

CONTACTO PET-SHEET.COM

Nuestro equipo de ventas profesionales y técnicos determinarán las características finales del producto y la solución material para la aplicación específica del cliente y proporcionarán al cliente una cotización y un cronograma detallado. Por favor, complete el formulario para contactar a nuestro equipo de ventas profesional.- Categoría

- Rollo de lámina de plástico APET

- Rollo de lámina de plástico GAG

- Rollo de lámina de plástico PETG

- Rollo de lámina de plástico RPET

- Rollo de lámina PET antiestática ESD

- Termoformado de PET en rollo

- Similar Products No related posts found.

PET-SHEET.COM

PET-SHEET.COM