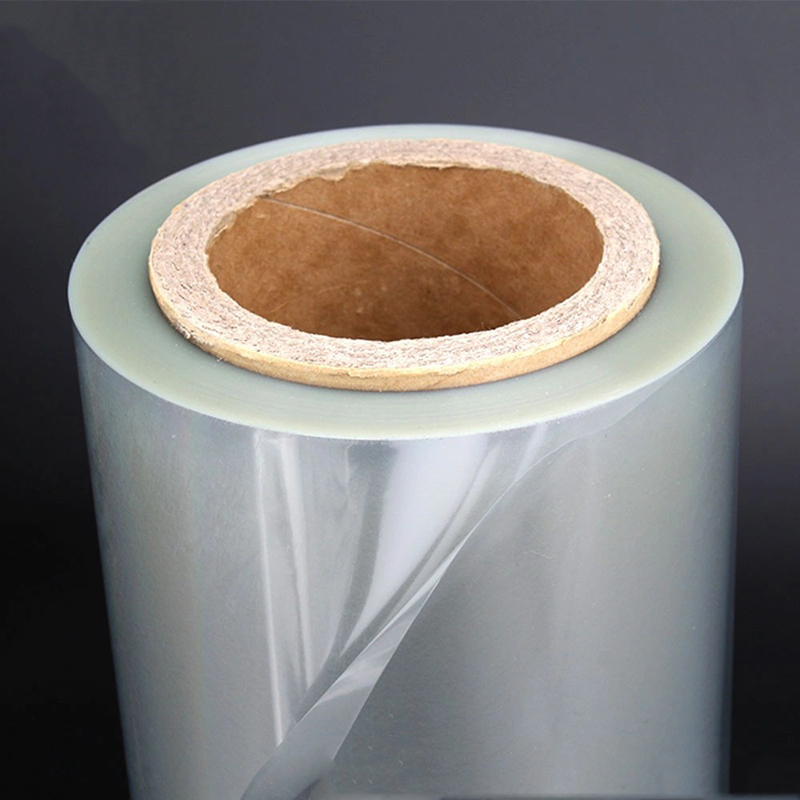

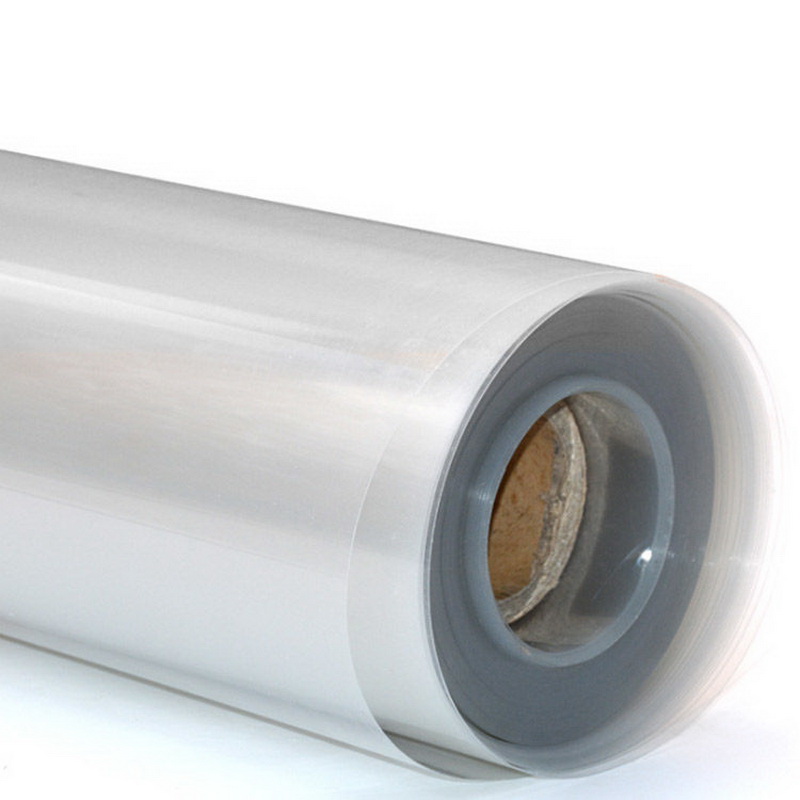

2.0mm PET Plastic Rolls

PET-SHEET.COM

PET-SHEET.COM

- Límites de producción:

- Gama de espesores: 0.18mm-1.8mm

- Gama de anchos: 350mm-1300mm

- Gama de colores: Transparente/Transparente/Negro/Blanco/Color personalizado

- MOQ: 5 toneladas (se aceptan muestras gratis)

- Aplicaciones: Bandeja termoformada / Bandeja electrónica / Bandeja para alimentos frescos / Envasado blíster

¿Está buscando esto? Thermoforming PET Sheet Roll. pet-sheet.com is Una fábrica enfocada en la fabricación y exportación de rígido Thermoforming PET Sheet Roll para termoformado o envasado en blíster. en cuanto a "2.0mm PET Plastic Rolls", Si nos deja sus requisitos como el grosor, ancho y aplicación del plástico PET, nuestro equipo de ventas profesional le cotizará el mejor precio competitivo.

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

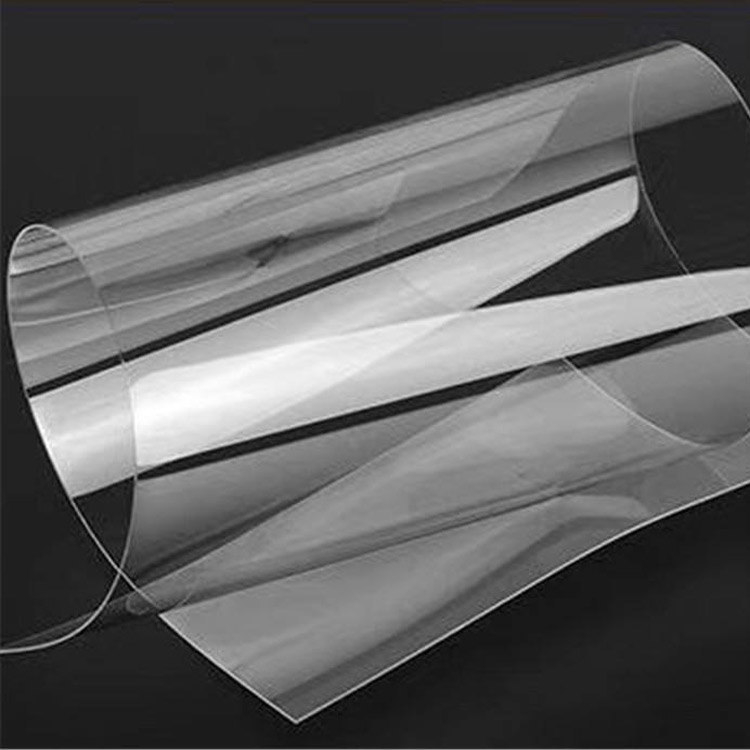

Product Introduction of 2.0mm PET Plastic Rolls

Our 2.0mm PET Plastic Rolls are designed for versatile and reliable packaging applications. Manufactured with premium-grade PET (Polyethylene Terephthalate), these rolls offer excellent strength, clarity, and durability, making them ideal for a variety of industries, including food, electronics, and consumer goods packaging.

Key Features

Thickness: 2.0mm, providing enhanced strength and rigidity.

High Durability: Resistant to impact, moisture, and environmental factors.

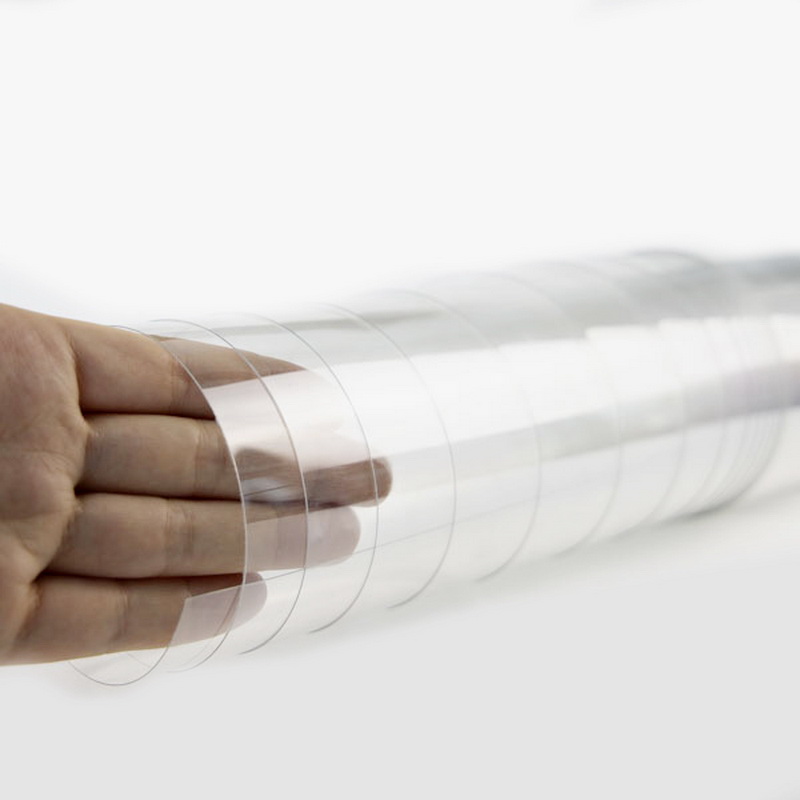

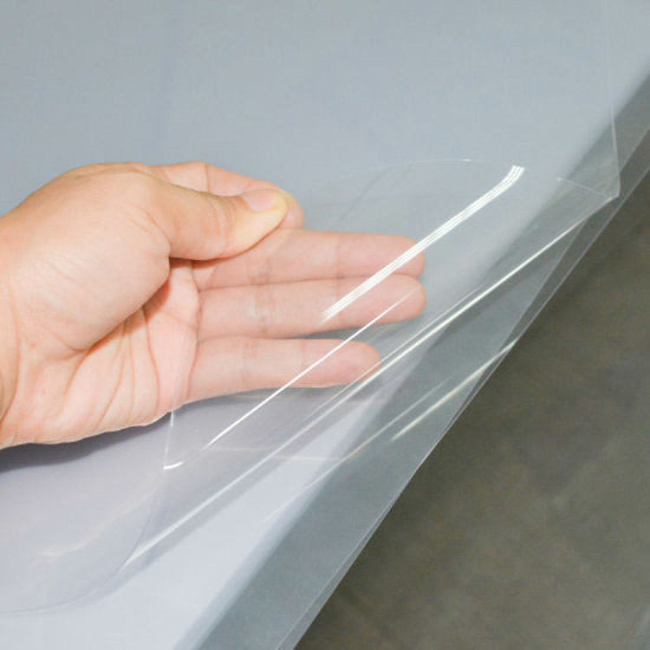

Superior Clarity: Crystal-clear finish for optimal product visibility.

Eco-Friendly: Made from recyclable PET material, promoting sustainability.

Customizable: Available in various widths and lengths to suit specific needs.

Cost-Effective: Provides a cost-efficient solution without compromising on quality.

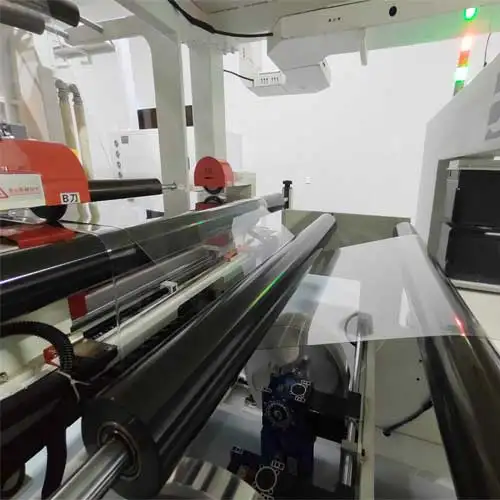

Production Process of 2.0mm PET Plastic Rolls

The production of 2.0mm PET Plastic Rolls involves a series of precise manufacturing steps to ensure high quality and durability:

- Raw Material Selection: High-quality PET resin is sourced from trusted suppliers, ensuring excellent strength, clarity, and environmental compatibility.

- Extrusion: The PET resin is heated and melted before being extruded through a die to form a continuous sheet of plastic. The thickness is carefully controlled to ensure a uniform 2.0mm thickness.

- Cooling and Solidifying: The extruded plastic sheet is cooled rapidly to solidify the material, maintaining its structural integrity and clarity.

- Stretching: The cooled sheet is then stretched to improve its mechanical properties, such as tensile strength and flexibility, ensuring it can withstand pressure and impact.

- Winding: The finished PET sheet is wound into large rolls, ready for cutting to customer-specific sizes or further processing.

- Quality Control: Each roll undergoes a strict quality control process, including visual inspections and material testing to ensure it meets industry standards for strength, clarity, and durability.

- Packaging: After passing inspection, the rolls are packaged and prepared for shipment to customers, ensuring they are delivered safely and securely.

This process guarantees that our 2.0mm PET Plastic Rolls offer the best in performance and durability for a variety of applications.

Product Advantages of 2.0mm PET Plastic Rolls

1. High Durability

The 2.0mm thickness provides excellent resistance to impact, tearing, and puncturing, ensuring long-lasting protection for packaged products.

2. Superior Clarity

PET plastic rolls offer a crystal-clear finish, enhancing product visibility and providing a professional, high-quality look for consumer-facing packaging.

3. Lightweight

Despite their strength, these rolls are lightweight, reducing overall shipping costs and offering a practical solution for many packaging applications.

4. Eco-Friendly

Made from 100% recyclable PET material, these plastic rolls contribute to sustainable packaging practices, aligning with eco-conscious business goals.

5. Chemical and Moisture Resistance

PET plastic is resistant to chemicals, moisture, and UV light, making these rolls ideal for packaging food, electronics, and pharmaceuticals that need protection from external elements.

6. Versatile Applications

Perfect for a wide range of industries, including food packaging, retail, electronics, and cosmetics. PET rolls are adaptable to various types of products, from heavy-duty items to delicate consumer goods.

7. Customizable Size

Available in different widths, lengths, and thicknesses to suit specific customer requirements, providing flexibility in packaging design.

8. Strong Sealability

PET rolls allow for strong and secure sealing, which is crucial for keeping products fresh and protected during storage and transportation.

9. Cost-Effective

Provides a high-performance packaging material at an affordable price, delivering value without compromising on quality or durability.

10. Excellent Processing Performance

Easy to convert and process, making it suitable for a variety of packaging techniques like thermoforming, vacuum forming, and blister packaging.

Product Application of 2.0mm PET Plastic Rolls

- Food Packaging

PET plastic rolls are commonly used in food packaging, providing a safe and protective barrier that preserves freshness while allowing for product visibility. Ideal for packaging items like snacks, bakery products, and frozen foods.

- Electronics Packaging

These rolls are ideal for packaging delicate electronic components, offering protection against dust, moisture, and physical damage. PET is often used for blister packs and protective covers for gadgets, cables, and devices.

- Cosmetics & Personal Care

PET plastic rolls are frequently used in the cosmetic and personal care industry for packaging high-end products like perfumes, lotions, and creams. Their clarity provides a sleek, professional appearance while offering product protection.

- Pharmaceutical Packaging

PET’s durability and resistance to moisture and chemicals make it a great choice for pharmaceutical packaging. It is used to protect medications, tablets, and supplements from contamination while maintaining product integrity.

- Retail & Consumer Goods Packaging

Ideal for a wide range of retail items, PET plastic rolls are used to package toys, hardware, tools, and consumer products, offering durability and a premium finish for both shelf display and shipping.

- Blister and Clamshell Packaging

The 2.0mm thickness is perfect for forming sturdy blister packs and clamshell packaging, ensuring secure and clear displays for a variety of consumer products.

- Toys and Gadgets

PET plastic rolls are ideal for packaging toys, gadgets, and small appliances, providing both visual appeal and secure protection during transit and display.

- Medical Devices and Equipment

PET plastic rolls are used in sterile packaging for medical devices, instruments, and other healthcare-related products. Their strength and resistance ensure safe handling and storage.

- Industrial and Automotive Parts

Strong and durable, PET plastic rolls are used to package various industrial and automotive components, offering protection during shipping and storage.

- Gift and Retail Packaging

PET plastic rolls are used in premium gift and retail packaging, providing a clear, visually appealing way to present products. The material is often used for custom packaging solutions and promotional displays.

¿Por qué elegir pet-sheet.com?

Producción de coextrusión

Producción de coextrusión

Inspeccion de calidad

Inspeccion de calidad

Embalaje seguro

Embalaje seguro

El tiempo de entrega

El tiempo de entrega

CONTACTO PET-SHEET.COM

Nuestro equipo de ventas profesionales y técnicos determinarán las características finales del producto y la solución material para la aplicación específica del cliente y proporcionarán al cliente una cotización y un cronograma detallado. Por favor, complete el formulario para contactar a nuestro equipo de ventas profesional.- Categoría

- Rollo de lámina de plástico APET

- Rollo de lámina de plástico GAG

- Rollo de lámina de plástico PETG

- Rollo de lámina de plástico RPET

- Rollo de lámina PET antiestática ESD

- Termoformado de PET en rollo

- Similar Products No related posts found.

PET-SHEET.COM

PET-SHEET.COM